Welcome to our Skills Special blog post. We always include a ‘skills’ item in our normal quarterly newsletter (sign up on the homepage) but, as skills is one of the common factors that brings everyone in the Electronics community together, we thought that we would start 2018 with a special newsletter and blog post. To set the scene, we start with a summary of the Government’s Industrial Strategy, as this provides the context.

Industrial Strategy

In November 2017 the Government published a new Industrial Strategy. This long-term plan aims to boost productivity and earning power throughout the UK with investment in skills, industries and infrastructure of the future.

The strategy states: “The world is undergoing a technological revolution. Artificial intelligence (AI) will transform the way we live and work … This fourth revolution [also known as Industry 4.0] is of a scale, speed and complexity that is unprecedented … blurring the lines between the physical, digital and biological worlds. It will disrupt nearly every sector … The UK is already a world leader in AI … UK innovators push boundaries in robotics and the internet of things.” The strategy also highlights the importance of improving intra-city transport and creating faster links between cities.

AI, robotics and transportation are picked out in the strategy as keys areas for focus and investment, and all are dependent on Electronics. As the strategy explains, its success will “depend on our ability to keep up with the pace with new sectors and emerging businesses.” For this to happen, a higher number of young people will need to study Electronics at university.

What is Industry 4.0?

Professor Klaus Schwab, Founder and Executive Chairman of the World Economic Forum, breaks down the meaning of ‘Industry 4.0’ in the December issue of Manufacturing Our Future (p. 10). Here’s a summary:

- Internet of things – traditional supply chains can become more digitised and connected.

- Big data and advanced analytics – allows targeted innovation, marketing and decision making.

- Robotics and automation – computing and communications systems increasingly linked to physical systems.

- Simulations, 3D printing and augmented reality – saves time and reduces materials as good are virtually modelled and tested.

Industrial Digitalisation Review

The Industrial Digitalisation Review was carried out to “assess how UK manufacturing can benefit from increasing digitalisation and technological change” and focused on the need for skills that are underpinned by Electronics. The leadership team also considered which digital technologies are most likely to create new industries and jobs, including AI and robotics. The result, the Made Smarter Review 2017, puts forward several recommendations, including strengthening the interaction with upcoming talent within universities through focused projects and placements.

AI

There is a lot of interest in investing in AI. A recent article by Consultancy.uk states “just over a fifth of UK businesses have already invested” and that “half of all UK organisations will have sunk over £10 million into digital technology by 2020”, however “concerns regarding a digital skills shortage are hampering efforts to get the most out of AI”. Paul Thompson, UK Digital Transformation Leader at Deloitte, says that “the UK isn’t living up to its digital potential” for this very reason. He continues, “educators, policymakers and business [need] to work more closely together, in order to meet the current and future demands of the UK’s economy”.

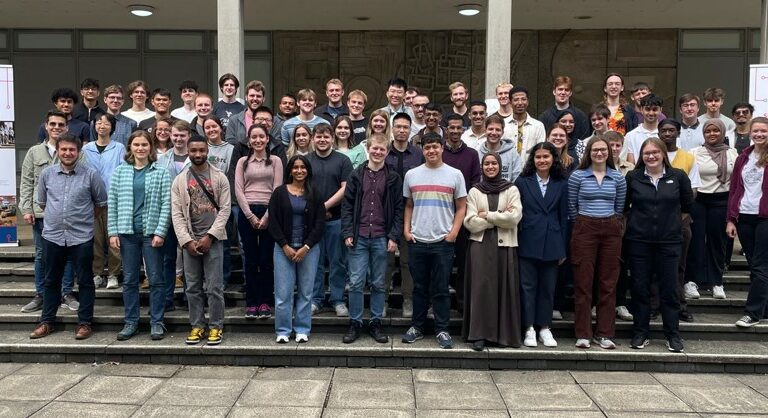

UKESF

In order to deliver the strategies detailed above and make transformational technologies a reality, the truth is that we need more people studying Electronics – from taking an interest in STEM subjects at school, following on to A-levels in subjects like Maths and Physics, and ultimately achieving a degree in Electronics at university. This is where the UKESF comes in.

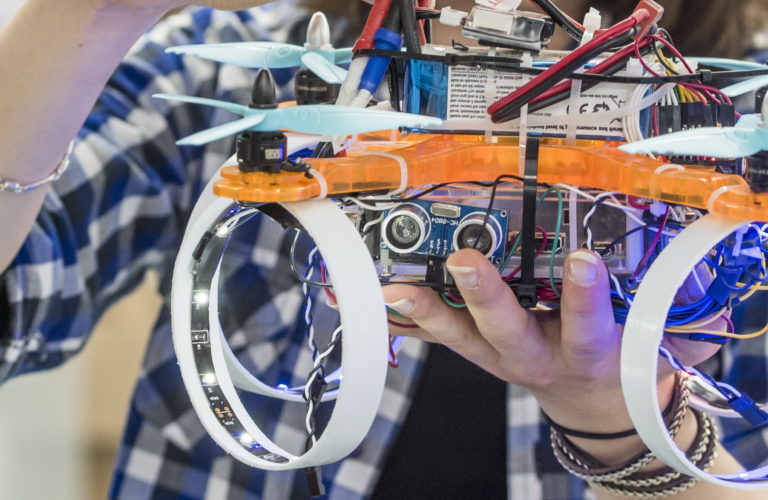

The work of the UKESF is clearly aligned with the recommendations set out in the Made Smarter Review 2017. Through the Scholarship Scheme, we partner the most dedicated Electronics undergraduates with leading companies for work placements and professional development. We also collaborate with other organisations and companies on a range of STEM-related initiatives for younger students.

Degree Apprenticeships

An important aspect of our policy work has been around the development of new apprenticeship standards, particularly at degree level (both Levels 6 and 7). There are now a number of standards approved by the Institute for Apprenticeships for use by employers.

As UKESF, we are supporting a group of employers to develop a new standard for Electronics Systems engineering at Level 7. However, the picture is still not complete and there are still some ‘gaps’; one of these is around Electro-Mechanical engineering. There has been some interest forming a Trailblazer (TB) group of employers to work on a Level 6 (Degree) apprenticeship for Electro-Mechanical Engineers. If you are interested to learn more or to get involved in the TB group for an Electro-Mechanical degree (Level 6) apprenticeship, then please let us know.

Skills Needs Survey

In the UK, particularly focused in South Wales, the compound semiconductor industry is expected to grow significantly over the next five or so years. There are expectations that the UK will be at the forefront of a global compound semiconductor market predicted to be worth £125bn by 2025. However, it is a highly technical sector with some very specific skills sets. In order that the UK can grow and flourish as an area of expertise in this global industry sector, it is essential to ensure that the appropriate educational and training capabilities are in place. Therefore, we would be grateful if you would spare a few minutes to complete this online questionnaire.

T-Levels

T-levels are new two-year technical qualifications that are expected to be introduced in colleges around 2020. The Government has made funds available to aid colleges in securing the placement opportunities, however the difficulty here lies in finding enough relevant employers local to each college to support the number of students requiring work placements. In order for the Engineering and Manufacturing T-Level to be introduced as widely as possible, Electronics companies need to be willing to offer work placements. The T-Levels are designed to be ‘employer-led’, so expressing an interest to a local college would be a positive first step in the right direction.

2018 – The Year of Engineering

As you will have seen in the media 2018 is the Year of Engineering. Amid all the razzamatazz and the numerous high profile events, if we are going to make a different we need to work on a local basis, one school at a time. Therefore, in collaboration with the University of Southampton, the UK Electronics Skills Foundation has created a high-impact but low-cost project, linked to the A-Level Physics curriculum. It would be great if TechWorks members could support the project. A donation of £1,000 will allow the UKESF to support teachers and pupils at two schools; together we can make a difference.